The fantastic updates keep coming from this production model crew!! OUTSTANDING!!

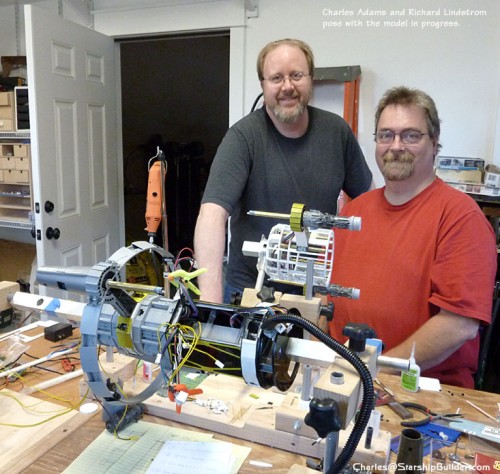

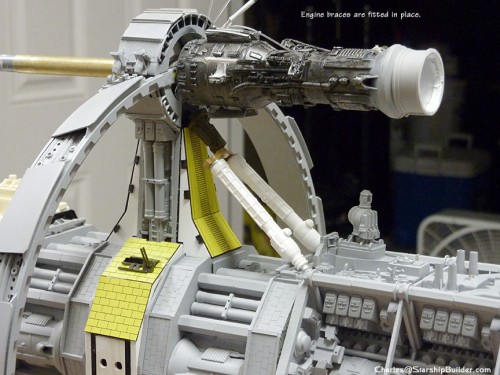

Richard was here for another marathon building session starting

Saturday. We are in the home stretch in our push toward final

delivery. The more we get done, however, the more it seems there is

still left to do! This is one complicated model. . .We installed the rear cooling module spotlights for a lighting test.

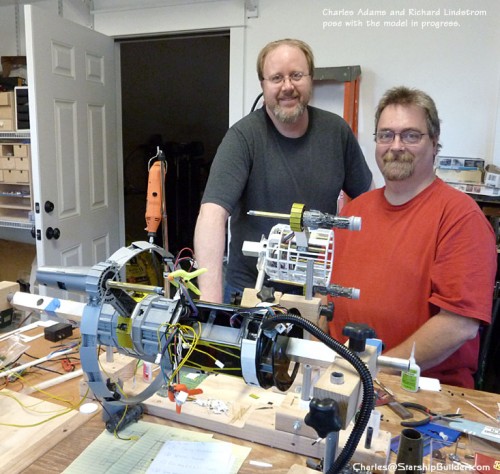

All spotlights are now on individually controlled circuits so the

lighting for each section of the ship can be adjusted independently

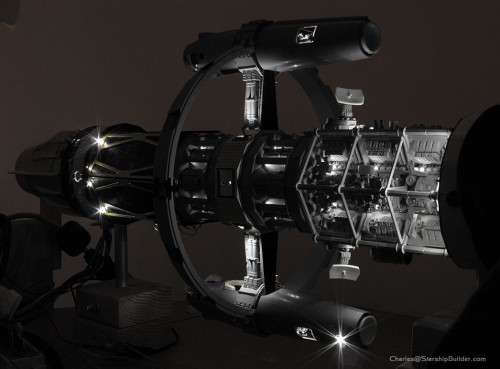

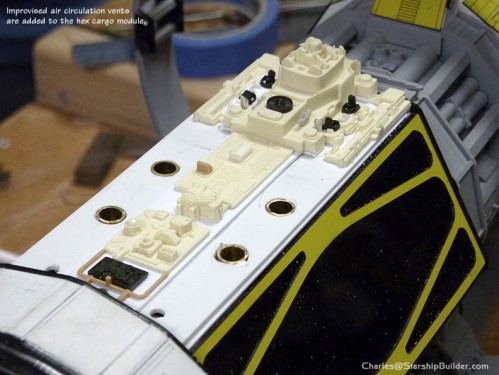

to balance out the effects.Because the open hex module creates a “choke point” inside the model,

there was too little room to run all the wires and fibers through

that area. This forced us to improvise some solutions. I added a rear

wire harness/umbilical to the aft cooling module that exits the left

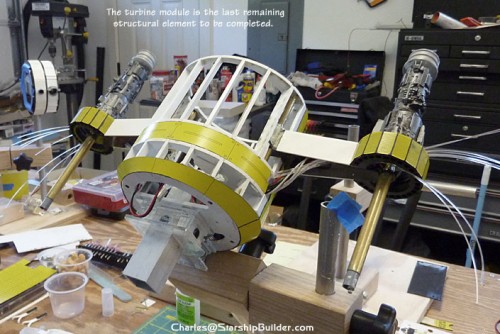

side of the model. I also had to redesign the electronics and wiring

inside the turbine module in order to get everything connected. We

now have a new circuit board in there and everything is ready for

final hookup and testing.To reduce heat buildup inside the model, I am stepping down the

supply voltage from 12V to as low as 5V. This means further lighting

tests will have to wait until the control box has been completed.

Fortunately, the wiring design is well laid out and modular so this

did not require any rewiring inside the ship. All I needed to do was

swap out some resistors on the internal circuit boards. We also added

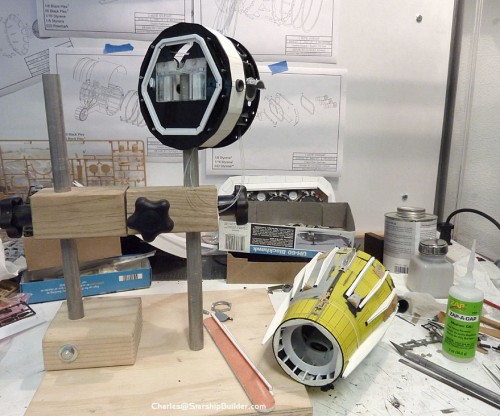

improvised air circulation vents to the hex cargo module.Before wrapping up work yesterday, we moved the model from its work

stand to the crate base in preparation for final delivery. We are

expecting triple digit temperatures in our area starting today and

lasting through the weekend. Since the shop is not air conditioned,

further progress will be slow until things cool down a bit.Thanks! 🙂

Charles